ASTM Standard Customized Steel Sand Casting Parts

- Packaging:

- Standard export packing or according to customers' specifict requirments.

- Supply Ability:

- 10 Pack/Packs per Day

- Port:

- Qingdao Port

Product Description

Product Show

Product Name | ASTM Standard Customized Steel Sand Casting Parts |

Quality Assurance | ISO9001:2015 Certified |

Material | Aluminum Alloy: 5052 /6061/ 6063 / 2017 / 7075 / etc. |

Brass Alloy: 3600/ 3602 / 2604 / H59 / H62 / etc. | |

Stainless Steel Alloy: 303 / 304 / 316 / 412 / etc. | |

Steel Alloy: Carbon Steel / Die Steel / etc. | |

Other Special Materials: Nickle / Titanium Alloy / etc. | |

We handle many other type of materials. Please contact us if your required material is not listed above. | |

Surface Treatment | Blacking,polishing,anodize,chrome plating,zinc plating,nickel plating,tinting |

Caliper, Inner diameter micrometer, OD diameter, Height Vernier Caliper, Hardness Tester, Ring Gauge, Infrared Spectrometer, Profile Projector Machine, Coordinate Measuring Machine, Roughness Meter, etc. | |

File Formats | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

Machining Equipment | Machining Center / CNC Lathes / Grinding Machines / Milling Machines / Lathes / Stamping Machines/ Full Automatic Lathe /etc. |

Agriculture Machinery: Cylinder Heads, Oil Pump, Clutch Housing, Steering Box Denfense: Blank Receiver, Trigger Guards Heavy Machinery: Rock breaker, Bearing Housings Mining: Chippers blades, Impellers, Wear Rings, Gear Housings Oil Gas: Gate Valve, Wellhead Control EQP, Wellhead EQP Transportation: Cylinder heads, Engine support, Intake manifolds, Suspension arm | |

Standard | ASTM, ASME, DIN, JIS, ISO, BS, API, EN,GB |

Capability | Output 120 tons per month. |

Company Advantage | 1. Quotation within 48 hours. 2. Quality you can rely on. 3. Zehan provides 100% satisfaction at world competitive prices. 4. We pay meticulous attention to details throughout the whole manufacturing process. 5. Rigorous QC standards, 100% inspection before shipping. 6. Strict delivery time control for each and every order. |

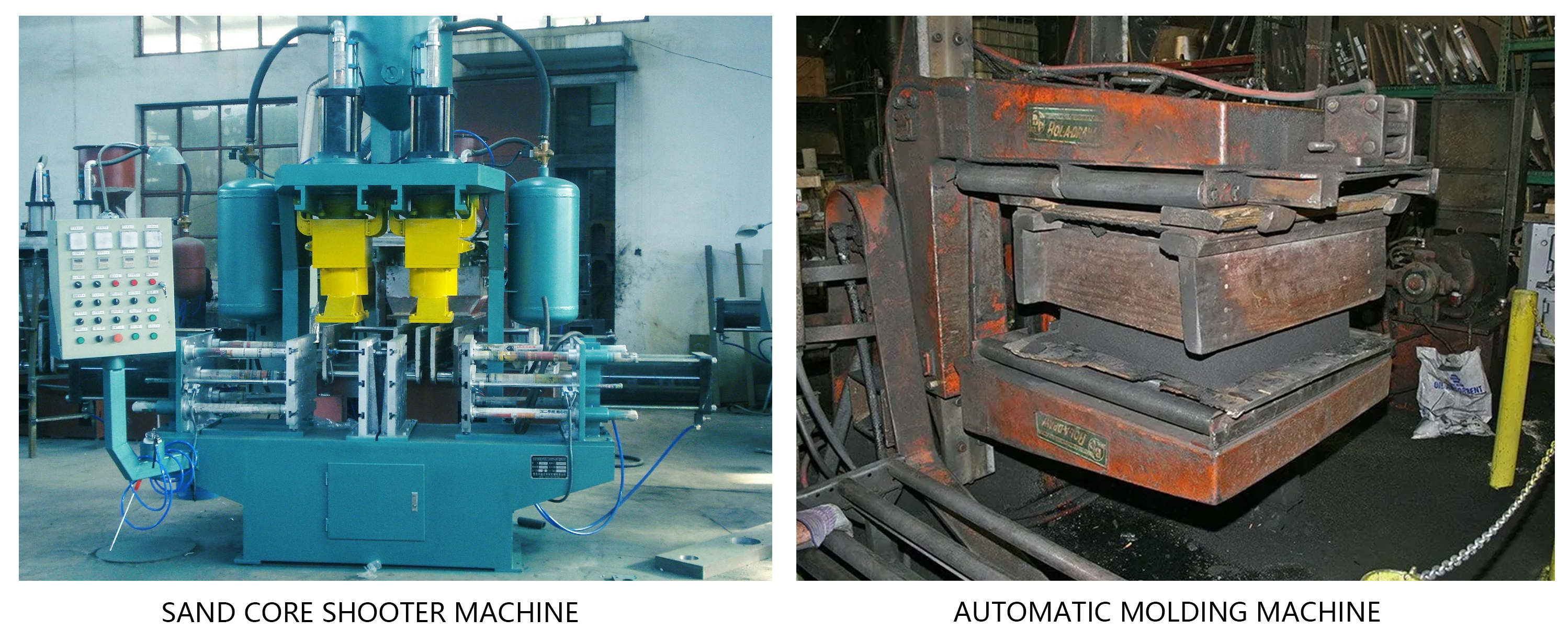

Process Show

What is Sand Casting

Sand casting is the most versatile among the manufacturing methods and gives the Engineers

the freedom to design complex parts from unlimited number of metals and alloys. Sand casting is a manufacturing process where the molten metal is poured into the expendable sand mold cavity either by gravity or by force, where it solidifies to form the cavity shape. 3D object formed by this process is also called casting. Most common sand castings include Engine blocks, cylinder heads etc.

the freedom to design complex parts from unlimited number of metals and alloys. Sand casting is a manufacturing process where the molten metal is poured into the expendable sand mold cavity either by gravity or by force, where it solidifies to form the cavity shape. 3D object formed by this process is also called casting. Most common sand castings include Engine blocks, cylinder heads etc.

Advantages of Sand Casting

1. Large parts can be produced.

2. Complex shapes can be cast easily.3. Large selection of metal to choose from.

4. Tooling and equipment cost is low compared to some other metal forming processes.

5. Scrap metal can be recycled.

6. Short lead compared to other similar processes.

Application Field

Manufacturing Process

1. The first step in the sand casting process is to create the mold for the casting. In an expendable mold process, this step must be performed for each casting. A sand mold is formed by packing sand into each half of the mold.

2. Once the mold has been made, it must be prepared for the molten metal to be poured.

3. After the molten metal has been poured into the mold cavity, manufacturing companies must wait for it to cool. Also, different types of metal take different lengths of time to cool. As the molten metal cools, it will revert from a liquid state back to a solid state.

4. After the predetermined solidification time has passed, the sand mold can simply be broken, and the casting removed.

2. Once the mold has been made, it must be prepared for the molten metal to be poured.

3. After the molten metal has been poured into the mold cavity, manufacturing companies must wait for it to cool. Also, different types of metal take different lengths of time to cool. As the molten metal cools, it will revert from a liquid state back to a solid state.

4. After the predetermined solidification time has passed, the sand mold can simply be broken, and the casting removed.

5. Cleaning all the sand and trimming After removing the casting from the sand.

6. Heat treatment & surface finishing.

6. Heat treatment & surface finishing.

Processing Capability

Testing Equipment

Company Profile

Qingdao Zehan Machinery Manufacturing Co., Ltd is an export-oriented high-tech enterprise specializing in fabrication of high-end metal parts, keeping a long-term and stably strategic cooperation with a number of world-famous enterprises since 2006. Our products are widely used in precision equipment, engineering machinery, construction, power facility, medical, animal husbandry, aviation, rail traffic and other industries. They have been widely sold in high-end market like North American and European countries.

Zehan has employee forces with excellent professional competence, strong executive ability, and high working efficiency. More than 80% of them achieved junior college degree or above. In addition to the standard regulation and professional guidance of daily production work, Zehan also provides,employees with regular training on technical basic theory and practical operation technology for years, which improves the front-line employees' overall professional quality while they working, and further improves the products’ quality and stability. It is our consistent tenet to pursue quality and make every product with high-quality materials, scientific design and exquisite process.

Qingdao Zehan Machinery Manufacturing Co., Ltd. sincerely welcomes more friends to cooperate with us, and create a better future together.

FAQ

1. How to prevent the formation of air holes in castings?

The effective methods to prevent bubbles are: reducing the gas content in the metal liquid, increasing the air permeability of sand mold, and adding an air riser at the top of the mold cavity.

In order to prevent sand expansion, the strength of sand mold and the rigidity of sand box should be increased, and the pressing force or fastening force when closing the box should be increased. In addition, the pouring temperature should be reduced to make the surface of molten metal crust earlier, so as to reduce the pressure of molten metal on the mold.

5. How to prevent sand inclusion?

Sand inclusion is a kind of groove and scar defect formed on the surface of castings, which is very easy to produce in wet mold casting of heavy plate castings. Avoiding large plane structure can effectively prevent sand inclusion.

6. How to identify the wrong type, wrong core and off-core?

1) Dislocation is the defect that one part of the casting is staggered with another part at the parting surface, which is usually caused by inaccurate positioning of the mold.

2) The core staggering is that the sand cores are staggered at the parting surface, which makes the inner cavity of the casting deform and the outer surface shape of the casting is correct.

3) Core deviation is caused by improper change of sand core position, which results in casting shape and size inconsistent with the drawing.

2. How to avoid the situation of sticky sand?

The surface of the casting is adhered to a layer of sand which is difficult to remove.It not only affects the appearance of casting, but also increases the workload of casting cleaning and cutting, and even affects the life of the machine.The method to prevent the formation of sand is to add coal powder in molding sand, and to brush the surface of the cast mold with anti-sand paint.

3. How to identify shrinkage?

3. How to identify shrinkage?

1) Observe the surface shape of casting defects. If the surface is uneven, very rough, and dark gray, the hole with irregular shape is shrinkage cavity.

2) If the location of the hole is at the final solidification thickening of the casting, or at the hot spot where the two walls intersect, and is located in the middle or upper part of the section, it is a shrinkage cavity.

3) The most concentrated hole defects on the thick and large section of steel castings are shrinkage or air shrinkage.

4. How to prevent sand expansion?

2) If the location of the hole is at the final solidification thickening of the casting, or at the hot spot where the two walls intersect, and is located in the middle or upper part of the section, it is a shrinkage cavity.

3) The most concentrated hole defects on the thick and large section of steel castings are shrinkage or air shrinkage.

4. How to prevent sand expansion?

In order to prevent sand expansion, the strength of sand mold and the rigidity of sand box should be increased, and the pressing force or fastening force when closing the box should be increased. In addition, the pouring temperature should be reduced to make the surface of molten metal crust earlier, so as to reduce the pressure of molten metal on the mold.

5. How to prevent sand inclusion?

Sand inclusion is a kind of groove and scar defect formed on the surface of castings, which is very easy to produce in wet mold casting of heavy plate castings. Avoiding large plane structure can effectively prevent sand inclusion.

6. How to identify the wrong type, wrong core and off-core?

1) Dislocation is the defect that one part of the casting is staggered with another part at the parting surface, which is usually caused by inaccurate positioning of the mold.

2) The core staggering is that the sand cores are staggered at the parting surface, which makes the inner cavity of the casting deform and the outer surface shape of the casting is correct.

3) Core deviation is caused by improper change of sand core position, which results in casting shape and size inconsistent with the drawing.

Product Categories : Sand Casting Parts > Steel Sand Castings

Premium Related Products

Hot Products

Custom High Precision Casting Mercedes Benz Truck PartsFoundry Good Quality Precision Iron Casting for PumpOEM Precision Stainless Steel Die Casting Spin ManufacturerSupplier Custom Good Quality High Precision Steel CastingChina Foundry Custom High Quality Casting Aluminiumprecision aluminum die casting housing partzinc die casting clock frameDifferent kind of stamping partPart made by plastic injectionAluminum Die Casting Part with ISO9001die casting mould makingCNC machining partPar38 heatsinkAluminum die casting partDie casting partanodizing part