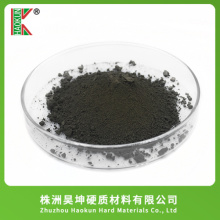

Custom Powder Metallurgy PM Sintered Copper Parts

- Packaging:

- Inner Packing: Anti-rust Paper/Film; Plastic Bag. Outer Packing: Carton/Nylon Belt Freight Packing: Wooden Case/Steel Belt; Pallet

- Supply Ability:

- 3000000 Piece/Pieces per Month Powder Metallurgy PM Sintered Copper Parts

- Port:

- NingBo, ShangHai

Product Description

How do We Work with Our Clients 1. For a design expert or a big company with your own engineering team: we prefer to receive a fully RFQ pack from you including drawing, 3D model, quantity, pictures; 2. For a start-up company owner or green hand for engineering: just send an idea that you want to try, you don‘t even need to know what casting is; 3. Our sales will reply you within 24 hours to confirm further details and give the estimated quote time; 4. Our engineering team will evaluate your inquiry and provide our offer within next 1~3 working days. 5. We can arrange a technical communication meeting with you and our engineers together anytime if required. Product Description

How do We Work with Our Clients 1. For a design expert or a big company with your own engineering team: we prefer to receive a fully RFQ pack from you including drawing, 3D model, quantity, pictures; 2. For a start-up company owner or green hand for engineering: just send an idea that you want to try, you don‘t even need to know what casting is; 3. Our sales will reply you within 24 hours to confirm further details and give the estimated quote time; 4. Our engineering team will evaluate your inquiry and provide our offer within next 1~3 working days. 5. We can arrange a technical communication meeting with you and our engineers together anytime if required. Product Description Technology | Powder Metallurgy | Metal injection moding | |

General Material | Fc0208/Fn0208 | 17-4Ph/4605 | |

Density | 6.7-6.8 | 7.7-7.8 | |

Hardness | Fc0208(20-30HRC) Fn0208(35-40HRC) | 17-4Ph(35-40HRC) 4605(45-50HRC) | |

Application | Medical apparatus and instruments Hardware field Automobile industry Home appliances | ||

Main Advantages1) Powder metallurgy can ensure the accuracy and uniformity of the material composition ratio.

Main Advantages1) Powder metallurgy can ensure the accuracy and uniformity of the material composition ratio.2) Suitable for producing products of the same shape and large quantities, low production cost.

3) The production process is not afraid of oxidation, and no material pollution will occur.

4) No subsequent machining processing is required, saving materials and reducing costs.

5) Most difficult metals and compounds, pseudo alloys, porous materials can only be manufactured by powder metallurgy

Certifications

Recommend Products view more >>Related ProductsWholesale Custom Made High Precision MIM Metal Injection Molded Auto Part$0.50 - $3.00 / Piece2000.0 PiecesCustomized MIM Injection Molds Metal Aviation Parts CNC Machining Process$0.50 - $3.00 / Piece2000.0 PiecesWholesale Custom Made High Precision Car Part Aluminum Injection Molding Parts$0.50 - $3.00 / Piece2000.0 PiecesWholesale Custom Metal Injection Molding Parts$0.50 - $3.00 / Piece2000.0 PiecesOEM Metal Injection Molding Powder Metallurgy Stainless Industryparts Companies$0.50 - $3.00 / Piece2000.0 PiecesCustomized MIM Metal Injection Molding Service Auto Parts$0.50 - $3.00 / Piece2000.0 Pieces Factory

Recommend Products view more >>Related ProductsWholesale Custom Made High Precision MIM Metal Injection Molded Auto Part$0.50 - $3.00 / Piece2000.0 PiecesCustomized MIM Injection Molds Metal Aviation Parts CNC Machining Process$0.50 - $3.00 / Piece2000.0 PiecesWholesale Custom Made High Precision Car Part Aluminum Injection Molding Parts$0.50 - $3.00 / Piece2000.0 PiecesWholesale Custom Metal Injection Molding Parts$0.50 - $3.00 / Piece2000.0 PiecesOEM Metal Injection Molding Powder Metallurgy Stainless Industryparts Companies$0.50 - $3.00 / Piece2000.0 PiecesCustomized MIM Metal Injection Molding Service Auto Parts$0.50 - $3.00 / Piece2000.0 Pieces Factory

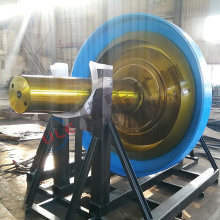

With our own automatic hydraulic machines, automatic mechanical pressers, vacuum furnaces, high-precision EDM machines, CNC machine equipment, grinders etc.

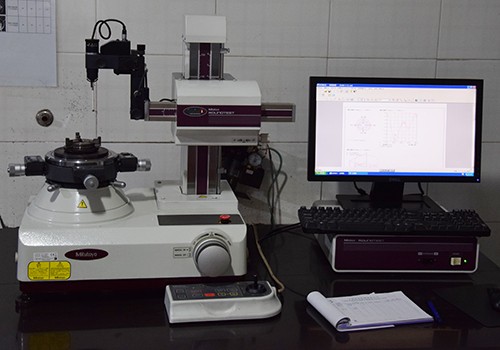

Quality control: universal testing machine, tensile testing machine, hardness equipment, density equipment, metalloscope, optics image instrument, etc.

About Us

Dewin, established in 2011, is a trading company engaged in the service for supply of engineered components. Our team has a rich experience of engineering industry for 18 years, such as machining, casting, stamping, sintering and forging. We always provide Dolphin Report with real information and help partner to control entire production processes. We provide services, called “Dolphin Services”, to make the international trade much easier. Packing & Delivery

Dewin, established in 2011, is a trading company engaged in the service for supply of engineered components. Our team has a rich experience of engineering industry for 18 years, such as machining, casting, stamping, sintering and forging. We always provide Dolphin Report with real information and help partner to control entire production processes. We provide services, called “Dolphin Services”, to make the international trade much easier. Packing & Delivery  Plastic Bag PackingGenerall Inner packing: Rust-proof, waterproof plastic bag, suitable for products with smaller dimension.

Plastic Bag PackingGenerall Inner packing: Rust-proof, waterproof plastic bag, suitable for products with smaller dimension. Anti-rust Paper PackingAnti-rust kraft paper for products with standard shapes or oil-immersed surfaces

Anti-rust Paper PackingAnti-rust kraft paper for products with standard shapes or oil-immersed surfaces Cartong/Belt+Wooden CaseFreight packing:Sealed wooden boxes or pallets to prevent product damage

Cartong/Belt+Wooden CaseFreight packing:Sealed wooden boxes or pallets to prevent product damage

FAQ 1. What are the differetiates between Dewin with other supplier?

FAQ 1. What are the differetiates between Dewin with other supplier?Profeession and reliability.

Our advantages are multiple available technologies, strong quality assurance, and good at project & supply chain management.

2. Is there a cost for Dewin service?

There is no additional cost above the product and tooling price except third party service.

3. Will I be able to visit the supplier myself?

First, all of our supply partner has undergone a series of screening and audit process, we can provide complete audit report to you.

Secondly, if you want to perform your own independent supplier audit procedure, our representitives can accompany and assit with you to achieve it.

4. How to deal with the quality problem?

a. With our partners we perform APQP at an early stage in each project.

b. Our factory must fully understand the quality concerns from customers and implement product & process quality requirements.

c. Our quality professionals who perform patrol inspection in our factories.We perform final inspection before the goods are packed.

d. We have 3rd party inspectors who perform final audit checks on the packed goods prior to dispatch from China.

5. Can you take responsibility for me?

Of course, I'm happy to help you! But I just take responsibility for my products.

Please offer a test report, if it was our fault, absolutely we can make a compensation for you, my friend!

6. Do you like to serve the client only with small orders?

We enjoy to grow up together with all our clients whatever big or small.

You will become bigger and bigger to be with us.

Contact us if you need more details on Pm Copper Parts. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Sintered Copper、Powder Metallurgy Sintered Copper Parts. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Powder Metallurgy Parts

Premium Related Products

Other Products

Hot Products

Custom High Precision Casting Mercedes Benz Truck PartsFoundry Good Quality Precision Iron Casting for PumpOEM Precision Stainless Steel Die Casting Spin ManufacturerSupplier Custom Good Quality High Precision Steel CastingChina Foundry Custom High Quality Casting Aluminiumprecision aluminum die casting housing partzinc die casting clock frameDifferent kind of stamping partPart made by plastic injectionAluminum Die Casting Part with ISO9001die casting mould makingCNC machining partPar38 heatsinkAluminum die casting partDie casting partanodizing part