Advanced Manufacturing and Factory Automation MES System

- Packaging:

- wooden packing

- Brand:

- DFMC

- Transportation:

- Ocean,Land,Air

- Place of Origin:

- DANDONG

- Port:

- Dalian,Shanghai,Tianjin

Product Description

Advanced Manufacturing and Factory Automation MES System

1. System Overview

MES(Manufacturing Execution System)can realize the integration and connection of the business and control systems, coordinate the production of the upper and lower links and integrate the various business management. MES System Software can provide real-time production data required for production management personnel at all levels, through intelligent analysis and tracking of production data, digging equipment and work potential constantly, to improve production efficiency and reduce production cost, and to improve the yield and reduce unplanned downtime, and to continuously improve management MES System Architecture objectives and to achieve lean production.

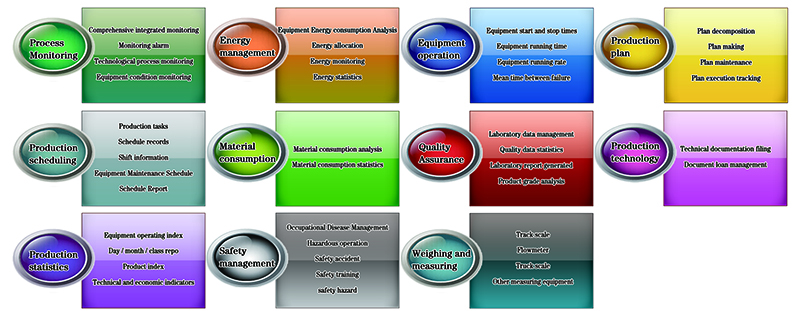

2. System Function

· Process monitoring

The production configuration screen is released through web, breaking through the regional limit. Online real-time monitoring of plant major Automated Control Services equipment operating parameters and operation status of important process flows, and integrating video monitoring signal. The visual picture expresses the field production process. Combined with real time database, the history replay function of configuration picture can be realized.

· Production scheduling

Collect business data during the production process and monitor the production control process and equipment operation of each process. Automatic summarize statistics and generate scheduling report. Timely identify problems or potential problems in the production process. And coordinate maintenance and security apartments to solve problems and ensure that production is carried out in a safe, orderly, and smooth manner.

· Production statistics

To store, count, and summarize professional data such as output, quality, equipment, materials, energy, etc. According to the statistics and analysis of departments and business, special statistical reports and trend charts can be formed. The effective and integrated display of useful information scattered in every link of production is carried out to realize the visualization of data.

· Energy management

To realize the collection and management of energy information of various production plants, such as water, electricity, gas and coal. Through the collection and analysis of energy data, it shows the energy consumption process to help users to determine abnormal energy consumption. Instant alarm on abnormal energy consumption and abnormal equipment. After the digital instrumentation of the process is completed, the system has the ability to count single-machine energy consumption, accurately calculate equipment efficiency, and manage process energy consumption.

· Security Management

Through security monitoring, safety pre-warning, quality standardization, hidden danger investigation and follow-up processing, the system uses digital technology measures and process control to improve the quality of safety management and avoid accidents.

· Equipment Management

Through the management and information collection of equipment inspections, maintenance and repairs, etc. Regulate and supervise the day-to-day work of equipment management and record planned and unplanned production downtime events. Using statistics to form chart analysis results such as equipment running rate and failure rate. Through real-time storage of the key operating parameters of the device, it helps the users to trace the abnormal equipment and supervise the operation.

· Quality management

Realize the management of important business processes such as quality inspection and testing in the production process. Collect, calculate and summarize quality data, and report alarms on abnormal data and alarm the key data abnormality to realize data statistics, analysis, publishing, sharing, and providing form printing function.

· Material consumption

Integrate the material consumption data of the workshop, including raw materials, consumables, reagents, large spare parts and so on. Combined with budget management, the cost assessment of production units can be realized. According to all the materials of a workshop, single material can be viewed separately. At the same time, according to the needs of users, it can increase the business of fixed materials, spare parts recovery/disposal, etc.

3.Application cases

China Railway Resources Yichun Luming Mining Co., Ltd.

China Gold Group Inner Mongolia Mining Wunutu Tushan Copper and Molybdenum Mine.

Pingshuo Coal Industry Limited.

Product Categories : MES System