High Performance Casting Aluminum Automobile Intake Manifold Lost Wax Investment Casting Parts

- Packaging:

- Standard export packing or according to customer's specific requirements

- Supply Ability:

- 600000 Piece/Pieces per Year

- Port:

- Qingdao

Product Description

Product Show

Product Name | |

Quality Assurance | ISO9001:2015 Certified |

Material | Aluminum Alloy:5052 /6061/ 6063 / 2017 / 7075 / etc. |

Brass Alloy:3600/ 3602 / 2604 / H59 / H62 / etc. | |

Stainless Steel Alloy:303 / 304 / 316 / 412 / etc. | |

Steel Alloy:Carbon Steel / Die Steel / etc. | |

Other Special Materials:Lucite / Nylon / Bakelite / etc. | |

We handle many other type of materials. Please contact us if your required material is not listed above. | |

Surface Treatment | Blacking,polishing,anodize,chrome plating,zinc plating,nickel plating,tinting |

Inspection | Projector etc. |

File Formats | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

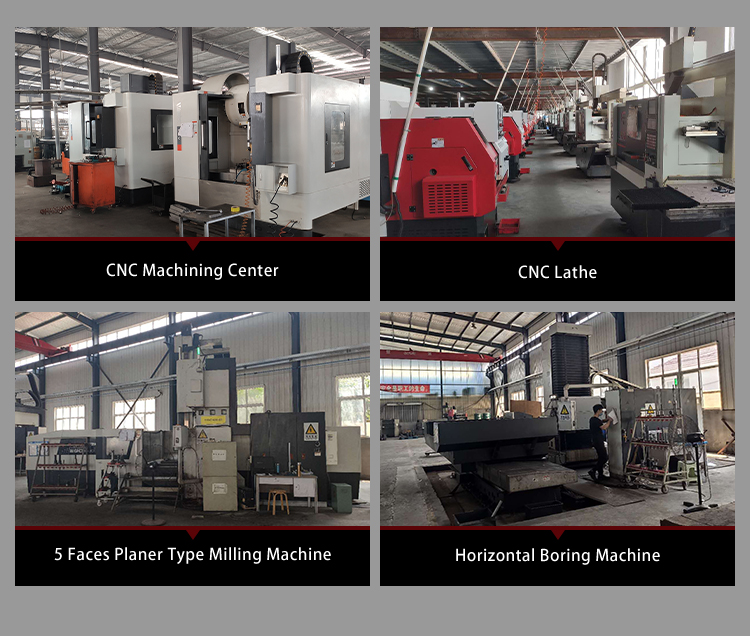

Machining Equipment | Machining Center / CNC Lathes / Grinding Machines / Milling Machines / Lathes / Stamping Machines/ Full Automatic Lathe /etc. |

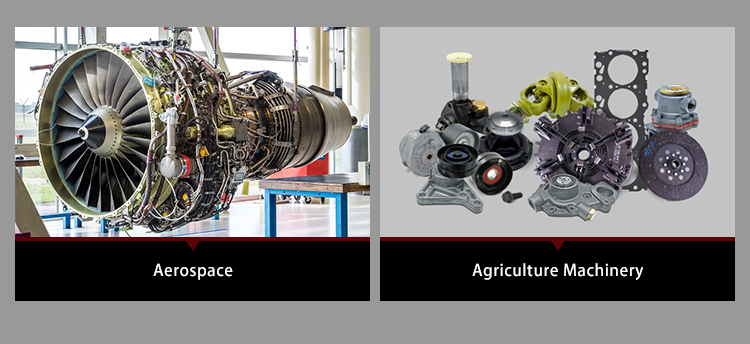

Application | Hardware and the whole mechanical and electronic industry, construction, hardware, equipment, engineering machinery and other large machinery, machine tools, ships, aerospace, automobiles, locomotives, electronics, computers,electrical appliances |

Standard | ASTM, ASME, DIN, JIS, ISO, BS, API, EN,GB |

Capability | Output 120 tons per month. |

Company Advantage | 1. High Precision, New Technology, Competitive Price for Casting and machining 2. Advanced casting machines available. 3. All kinds of facility, CNC Machining, turning, milling, tapping, drilling, polishing, punching, etc... 4. Competitive Prices, Excellent Service, and Good Lead Time. |

Company Profile

Qingdao Zehan Machinery Manufacturing Co., Ltd is a leading international manufacturer with 15+ years of group experience in rapid prototyping and production for metal & plastic components. We are an export-oriented high-tech enterprise specializing in fabrication of high-end metal parts, keeping a long-term and stably strategic cooperation with a number of world-famous enterprises. Our products are widely used in precision equipment, engineering machinery, construction machinery, power facility, agricultural machinery, animal husbandry, aviation, rail traffic and other industries. They have been widely sold in high-end market like North American and European countries. As a leading components manufacturing enterprise integrating with the digital management and production technology, Zehan has successively passed and introduced ISO9001 quality system, ERP management system, DNC system and PLM system. CNC equipment, automatic machines and auto test facilities are employed in all processing and manufacturing sectors. Covering extensive & well-adapted types, some machines have already reached the world class level. It is our consistent tenet to pursue quality and make every product with high-quality materials, scientific design and exquisite process. Qingdao Zehan Machinery Manufacturing Co., Ltd. sincerely welcomes more friends to cooperate with us, and create a better future together.

Machining Equipment

Process Show

Manufacturing Process

Application Field

Customers VIsiting

FAQ

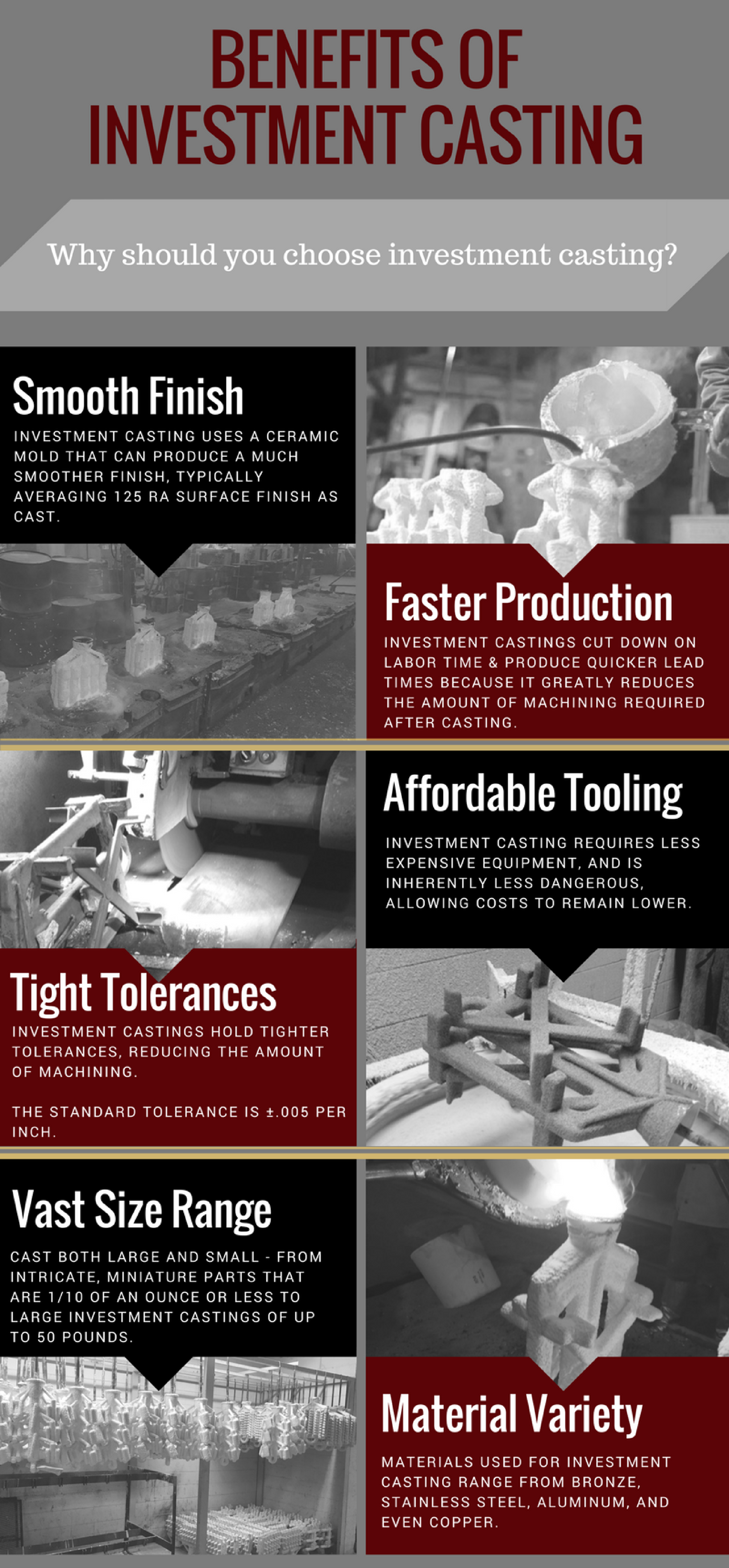

What are the factors that affect the dimensional accuracy of precision casting pieces?

Generally, the dimensional accuracy of precision casting parts is affected by many factors, such as casting structure, casting material, mold making, shell making, roasting and pouring, etc. Any unreasonable setting and operation of any link will change the shrinkage rate of casting, resulting in the deviation of the dimensional accuracy of casting from the requirements.

Generally, the dimensional accuracy of precision casting parts is affected by many factors, such as casting structure, casting material, mold making, shell making, roasting and pouring, etc. Any unreasonable setting and operation of any link will change the shrinkage rate of casting, resulting in the deviation of the dimensional accuracy of casting from the requirements.

What are the inspection requirements for the surface quality of precision casting parts?

1.No slag, sand and other casting defects are allowed on the processing surface;

2.no flying burrs;

3.No scratches or bumps on the processing surface; 4.Sharp angles shall be ensured at the intersection of the grinding surface and the processing surface.

What are the technical requirements of precision casting parts?

1.Material requirements.The main hardness, tensile strength, elongation, impact toughness.

2.Dimensional accuracy and position accuracy.Different castings have different requirements, adopt different size and geometric tolerance standard and different tolerance class.

3.Stipulate acceptance requirements for other defects of castings according to use requirements.Such as porosity, sand hole,shrinkage, shrinkage, slag, sand, crack.

4.Requirements for defect repair.Mark the quantity, material, processing precision, casting implementation standard, appearance treatment of non-processed surface, weight, casting round corners, casting shall not have pores, sand holes, cracks and other defects.

What kind of products could be made in investment casting?

Investment casting process is suitable for products less than 100kg, and it is flexible for product design, no matter how complex it is. So investment casting can make almost all the small products.

For larger products, sand casting is preferred.

What type of tooling is required for investment casting?

A split aluminum tool or die is used to create a wax pattern, which is then coated with layers of stucco and ceramic material.

Before pouring the alloy, wax will be first melted away, which is where the term “lost wax casting” originated. In other processes(forging, stamping, Die Casting ) ,tooling is quite much more complex and expensive.

What general tolerances can we meet for an investment casting part?

For lost wax investment castings, we can reach general tolerances CT7-CT8. And for smaller precision parts, CT5-CT6 can be available.

1.No slag, sand and other casting defects are allowed on the processing surface;

2.no flying burrs;

3.No scratches or bumps on the processing surface; 4.Sharp angles shall be ensured at the intersection of the grinding surface and the processing surface.

What are the technical requirements of precision casting parts?

1.Material requirements.The main hardness, tensile strength, elongation, impact toughness.

2.Dimensional accuracy and position accuracy.Different castings have different requirements, adopt different size and geometric tolerance standard and different tolerance class.

3.Stipulate acceptance requirements for other defects of castings according to use requirements.Such as porosity, sand hole,shrinkage, shrinkage, slag, sand, crack.

4.Requirements for defect repair.Mark the quantity, material, processing precision, casting implementation standard, appearance treatment of non-processed surface, weight, casting round corners, casting shall not have pores, sand holes, cracks and other defects.

What kind of products could be made in investment casting?

Investment casting process is suitable for products less than 100kg, and it is flexible for product design, no matter how complex it is. So investment casting can make almost all the small products.

For larger products, sand casting is preferred.

What type of tooling is required for investment casting?

A split aluminum tool or die is used to create a wax pattern, which is then coated with layers of stucco and ceramic material.

Before pouring the alloy, wax will be first melted away, which is where the term “lost wax casting” originated. In other processes(forging, stamping, Die Casting ) ,tooling is quite much more complex and expensive.

What general tolerances can we meet for an investment casting part?

For lost wax investment castings, we can reach general tolerances CT7-CT8. And for smaller precision parts, CT5-CT6 can be available.

Product Categories : Investment Casting Parts > Investment Casting Parts

Premium Related Products

Other Products

Hot Products

Custom High Precision Casting Mercedes Benz Truck PartsFoundry Good Quality Precision Iron Casting for PumpOEM Precision Stainless Steel Die Casting Spin ManufacturerSupplier Custom Good Quality High Precision Steel CastingChina Foundry Custom High Quality Casting Aluminiumprecision aluminum die casting housing partzinc die casting clock frameDifferent kind of stamping partPart made by plastic injectionAluminum Die Casting Part with ISO9001die casting mould makingCNC machining partPar38 heatsinkAluminum die casting partDie casting partanodizing part