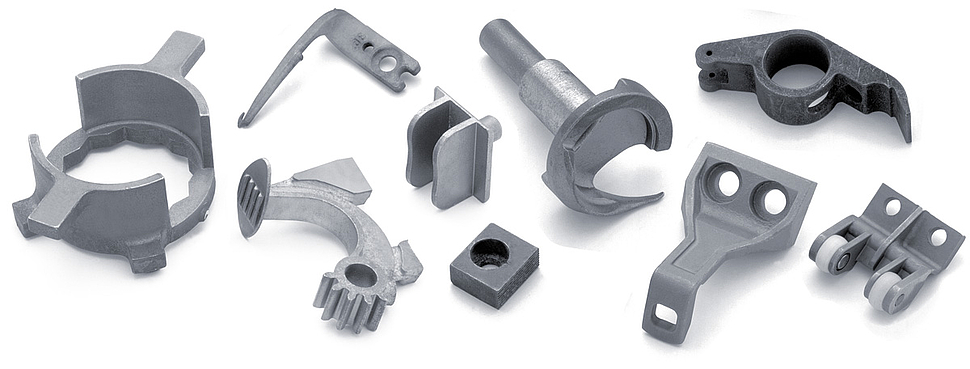

Custom OEM Casting Stainless Steel 306L Pump Spare Parts Lost Wax Investment Casting Precision Parts

- Packaging:

- Standard export packing or according to customers' specifict requirments.

- Supply Ability:

- 10 Pack/Packs per Day

- Port:

- Qingdao Port

Product Description

Product Show

Product Name | Custom OEM Casting Stainless Steel 306L Pump Spare Parts Lost Wax Investment Casting Precision Parts |

Quality Assurance | ISO9001:2015 Certified |

Material | Aluminum Alloy:5052 /6061/ 6063 / 2017 / 7075 / etc. |

Brass Alloy:3600/ 3602 / 2604 / H59 / H62 / etc. | |

Stainless Steel Alloy:303 / 304 / 316 / 412 / etc. | |

Steel Alloy:Carbon Steel / Die Steel / etc. | |

Titanium Alloy: Grade 1/Grade 2/Grade 2 H/Grade 3/Grade 5/etc. | |

We handle many other type of materials. Please contact us if your required material is not listed above. | |

Surface Treatment | Blacking,polishing,anodize,chrome plating,zinc plating,nickel plating,tinting |

Inspection | Caliper, Inner diameter micrometer, OD diameter, Height Vernier Caliper, Hardness Tester, Ring Gauge, Infrared Spectrometer, Profile Projector Machine, Coordinate Measuring Machine, Roughness Meter, etc. |

File Formats | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

Machining Equipment | Machining Center / CNC Lathes / Grinding Machines / Milling Machines / Lathes / Stamping Machines/ Full Automatic Lathe /etc. |

Application | Aerospace&Military industry: Jet engine airfoils. Trigger guards and black receiver. Energy: Anvil, Gate Valve, wellhead control EQP, wellhead EQP. Mining&Heavy machinery: Gear housings,Jaw plates,Rock breaker, Excavator parts Agriculture machinery: Tractor parts, Root grapple rake attachment Pumps&Valves: All kinds of pumps and valves. Transportation: Cylinder heads, Engine support, Suspension arm, Front and Rear brake calipers. |

Standard | ASTM, ASME, DIN, JIS, ISO, BS, API, EN,GB |

Capability | Output 120 tons per month. |

Company Advantage | 1. Quotation within 48 hours. 2. Quality you can rely on. 3. Zehan provides 100% satisfaction at world competitive prices. 4. We pay meticulous attention to details throughout the whole manufacturing process. 5. Rigorous QC standards, 100% inspection before shipping. 6. Strict delivery time control for each and every order. |

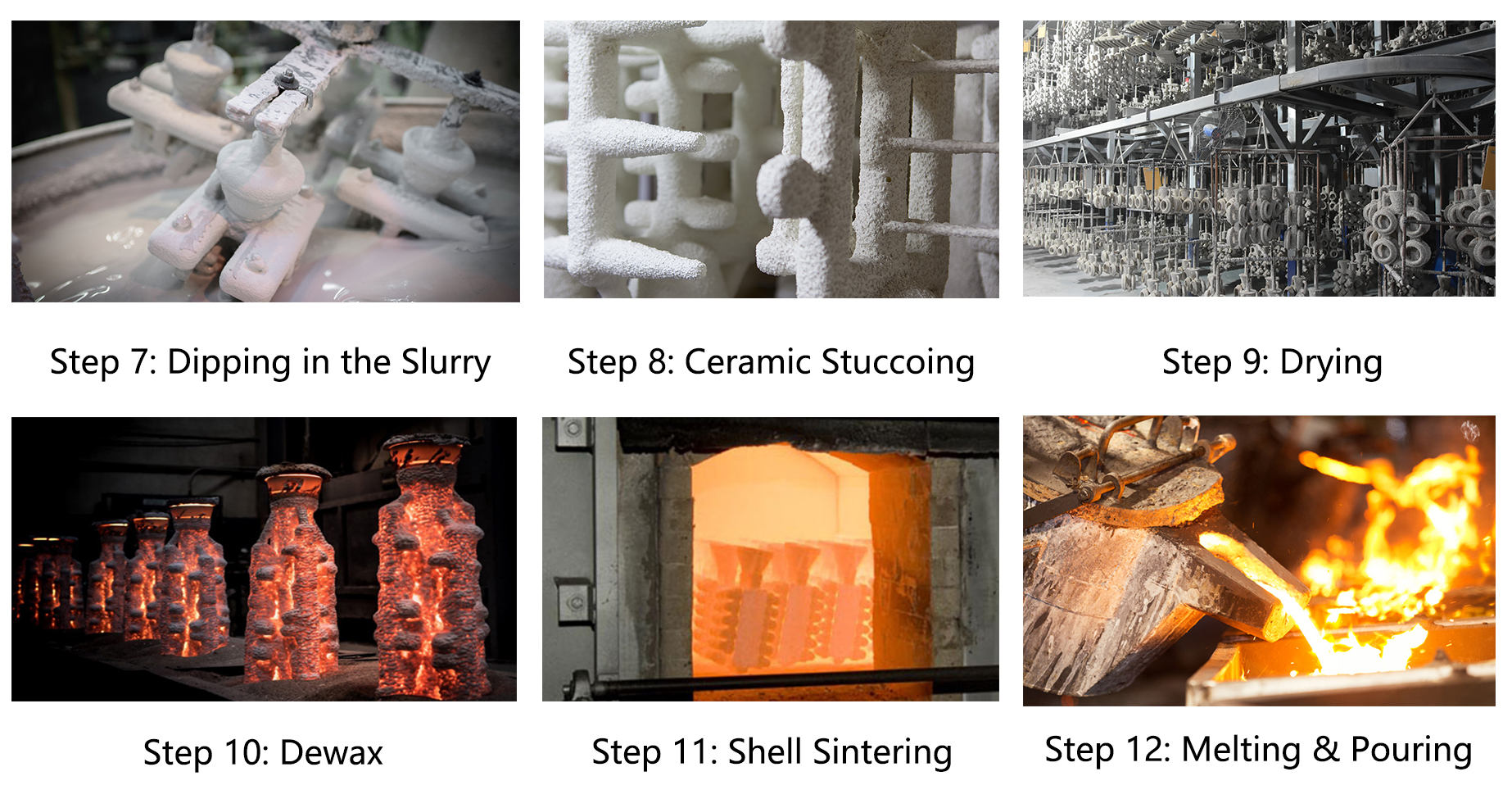

Process Show

What is Precision Casting

Investment casting refers to the formation of ceramics around a wax pattern to form a shell for casting molten metal. Once wax patterns are created, they are melted into the gate system, immersed in slurry and sand to form a layered shell, and then replaced by molten metal such as stainless steel, aluminum, or the like.

Advantages of Precision Casting

1. Parts can be casted with little or no machining.

2. The accuracy of investment casting is second to none.3. It is possible to produce a very wide variety of products across different industries.

4. Smooth surface without a parting line.

Application Field

Manufacturing Process

1.2.Mode design and management. First the mode should be designed.

3.4.Injection wax or plastic pattern, wax patterns are typically made by injecting wax into a metal tool or “die”.5.6.Pattern wax assembly (tree). It is typically uneconomical to make small parts one at a time, so wax patterns are typically attached to a wax “sprue”.

7.8.Ceramic dipping.The assembly is then dipped into a high-grade ceramic slurry to build a ceramic shell around the wax tree.

9.Drying: Hang these pattern assemblies in the room temperature for drying.

10.Dewaxing.The wax inside the newly built shell is now removed by putting the shell in a steam-dewaxing autoclave or flash fire furnace.

11.12.Sintering&Pouring. Before the metal is poured into the ceramic mold or “shell”, the mold is preheated to a specific temperature to prevent the molten alloy from solidifying or “freezing off” before the entire mold is filled.

13.Shell Removing. After Cooling,Break the ceramic shell and cut the individual investment castings from the sprue. Then remove the excess metal from casting body by grinding.

14.Shoot Blasting.To remove scales and achieve better surface finish, investment castings will be shot blasted or sand blasted by small steel balls.So all the foundries must be equipped with shot blasting machines.

15.Visual Inspection. Inspection is also a step for investment castings quality control.ur QC will do dimensional inspection, 100% surface inspection, inner defects inspection and other inspection jobs according to requirements of products.

Processing Capability

Testing Equipment

Company Profile

Qingdao Zehan Machinery Manufacturing Co., Ltd is an export-oriented high-tech enterprise specializing in fabrication of high-end metal parts, keeping a long-term and stably strategic cooperation with a number of world-famous enterprises since 2006. Our products are widely used in precision equipment, engineering machinery, construction, power facility, medical, animal husbandry, aviation, rail traffic and other industries. They have been widely sold in high-end market like North American and European countries.

Zehan has employee forces with excellent professional competence, strong executive ability, and high working efficiency. More than 80% of them achieved junior college degree or above. In addition to the standard regulation and professional guidance of daily production work, Zehan also provides,employees with regular training on technical basic theory and practical operation technology for years, which improves the front-line employees' overall professional quality while they working, and further improves the products’ quality and stability. It is our consistent tenet to pursue quality and make every product with high-quality materials, scientific design and exquisite process.

Qingdao Zehan Machinery Manufacturing Co., Ltd. sincerely welcomes more friends to cooperate with us, and create a better future together.

FAQ

1.What are the factors that affect the dimensional accuracy of precision casting pieces?

Generally, the dimensional accuracy of precision casting parts is affected by many factors, such as casting structure, casting material, mold making, shell making, roasting and pouring, etc. Any unreasonable setting and operation of any link will change the shrinkage rate of casting, resulting in the deviation of the dimensional accuracy of casting from the requirements.

2. What are the products of precision casting?

1)Aluminum Casting: general aluminum casting | aluminum box body

2)Copper and aluminum casting: copper plate, copper sleeve | precision copper casting

3)Steel castings: large steel castings | small steel castings | precision steel castings | CDL1 | CGAS | CGKD | CGKA | CGA

4)Copper aluminum casting

5)Tungsten iron

3. In what fields can precision casting products be applied?

Precision casting products are used in all industrial sectors, especially electronics, petroleum, chemical, energy, transportation, light industry, textile, pharmaceutical, medical devices, pumps and valves.

4. What is the precision of precision casting?

Precision casting is a casting method compared with the traditional casting process. It can obtain relatively accurate shape and high casting precision. Precision casting is a finished product after casting, no other processing is required, or the amount of processing is small. It is mainly used for important and complex parts and components. Precision casting the best dimensional accuracy can be controlled within IT8 standard tolerances.

5. What are the inspection requirements for the surface quality of precision casting parts?

2)Copper and aluminum casting: copper plate, copper sleeve | precision copper casting

3)Steel castings: large steel castings | small steel castings | precision steel castings | CDL1 | CGAS | CGKD | CGKA | CGA

4)Copper aluminum casting

5)Tungsten iron

3. In what fields can precision casting products be applied?

Precision casting products are used in all industrial sectors, especially electronics, petroleum, chemical, energy, transportation, light industry, textile, pharmaceutical, medical devices, pumps and valves.

4. What is the precision of precision casting?

Precision casting is a casting method compared with the traditional casting process. It can obtain relatively accurate shape and high casting precision. Precision casting is a finished product after casting, no other processing is required, or the amount of processing is small. It is mainly used for important and complex parts and components. Precision casting the best dimensional accuracy can be controlled within IT8 standard tolerances.

5. What are the inspection requirements for the surface quality of precision casting parts?

1)No slag, sand and other casting defects are allowed on the processing surface;

2)No flying burrs;

3)No scratches or bumps on the processing surface;

4)Sharp angles shall be ensured at the intersection of the grinding surface and the processing surface.

6.What are the technical requirements of precision casting parts?

2)No flying burrs;

3)No scratches or bumps on the processing surface;

4)Sharp angles shall be ensured at the intersection of the grinding surface and the processing surface.

6.What are the technical requirements of precision casting parts?

1) Material requirements.The main hardness, tensile strength, elongation, impact toughness.

2) Dimensional accuracy and position accuracy.Different castings have different requirements, adopt different size and geometric tolerance standard and different tolerance class.

3) Stipulate acceptance requirements for other defects of castings according to use requirements.Such as porosity, sand hole, shrinkage, shrinkage, slag, sand, crack.

4) Requirements for defect repair.Mark the quantity, material, processing precision, casting implementation standard, appearance treatment of non-processed surface, weight, casting round corners, casting shall not have pores, sand holes, cracks and other defects.

2) Dimensional accuracy and position accuracy.Different castings have different requirements, adopt different size and geometric tolerance standard and different tolerance class.

3) Stipulate acceptance requirements for other defects of castings according to use requirements.Such as porosity, sand hole, shrinkage, shrinkage, slag, sand, crack.

4) Requirements for defect repair.Mark the quantity, material, processing precision, casting implementation standard, appearance treatment of non-processed surface, weight, casting round corners, casting shall not have pores, sand holes, cracks and other defects.

Product Categories : Investment Casting Parts > Investment Casting Parts

Premium Related Products

Other Products

Hot Products

Custom High Precision Casting Mercedes Benz Truck PartsFoundry Good Quality Precision Iron Casting for PumpOEM Precision Stainless Steel Die Casting Spin ManufacturerSupplier Custom Good Quality High Precision Steel CastingChina Foundry Custom High Quality Casting Aluminiumprecision aluminum die casting housing partzinc die casting clock frameDifferent kind of stamping partPart made by plastic injectionAluminum Die Casting Part with ISO9001die casting mould makingCNC machining partPar38 heatsinkAluminum die casting partDie casting partanodizing part