Customized CNC Machining Parts Aluminum Motorcycle Hub Axle Gasket for Racing Parts

- Packaging:

- Carton with inner plastic film or as customers' requirments.

- Supply Ability:

- 100000 Piece/Pieces per Month

- Port:

- Qingdao Port

Product Description

Product Show

Product Name | Customized CNC Machining Parts Aluminum Motorcycle Hub Axle Gasket for Racing Parts | ||||||

Quality Assurance | ISO9001:2015 Certified | ||||||

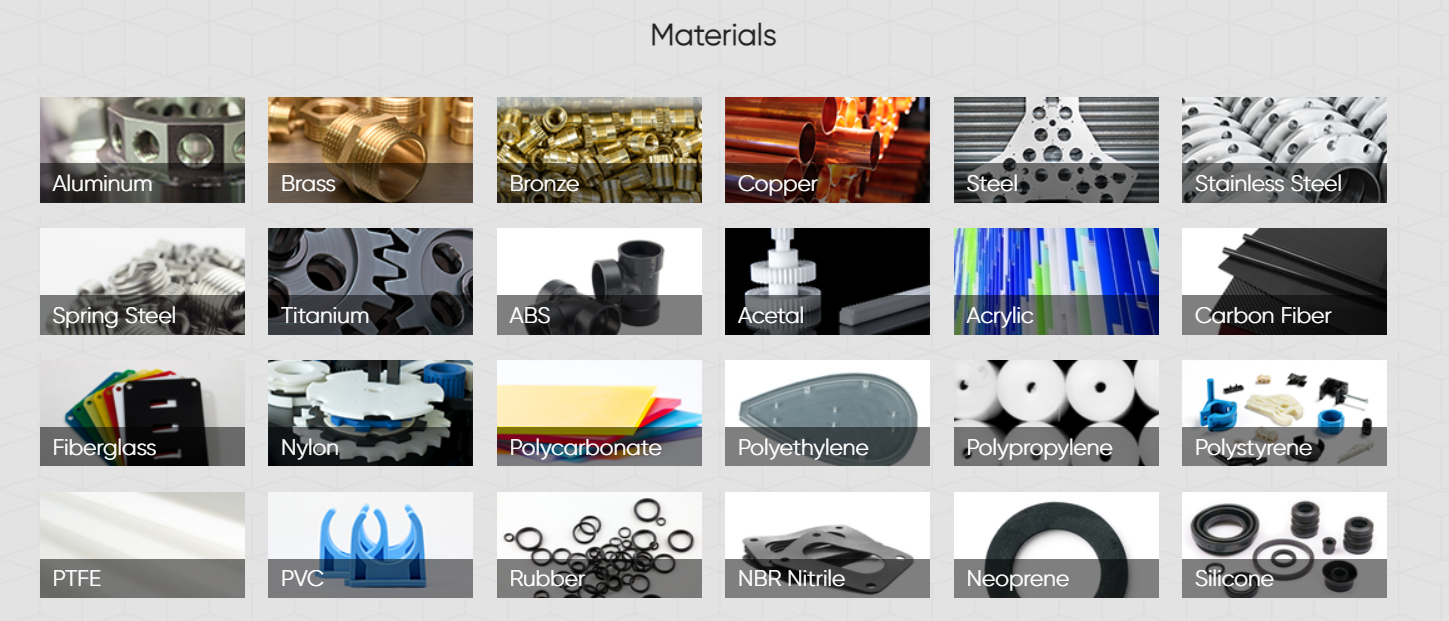

Material | Aluminum Alloy: 5052 /6061/ 6063 / 2017 / 7075 / etc. | ||||||

Brass Alloy: 3600/ 3602 / 2604 / H59 / H62 / etc | |||||||

Stainless Steel Alloy: 303 / 304 / 316 / 412 / etc. | |||||||

Steel Alloy:Carbon Steel / Die Steel / etc. | |||||||

Other Special Materials: Lucite / Nylon / Bakelite / etc. | |||||||

We handle many other type of materials. Please contact us if your required material is not listed above. | |||||||

Surface Treatment | Blacking,polishing,anodize,chrome plating,zinc plating,nickel plating,tinting | ||||||

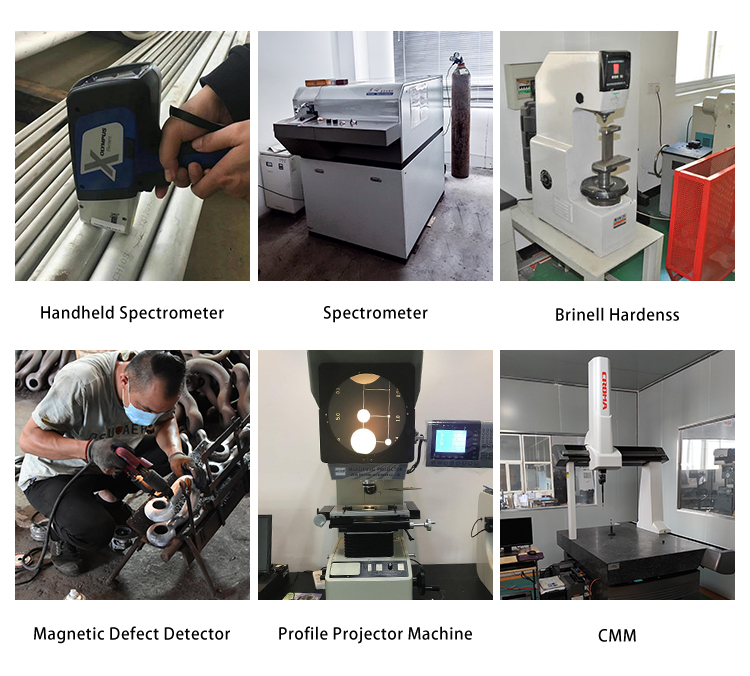

Inspection | Projector,Coordinate Measuring Machine, Visual Quality Standard, Roughness Tester, Hardness Tester, etc. | ||||||

File Formats | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. | ||||||

Machining Equipment | Machining Center / CNC Lathes / Grinding Machines / Milling Machines / Lathes / Stamping Machines/ Full Automatic Lathe /etc. | ||||||

Application | Aviation, shipbuilding, power generation industry processing propeller, engine, generator and turbine blade parts,Medical equipment industry. | ||||||

Standard | ASTM, ASME, DIN, JIS, ISO, BS, API, EN,GB | ||||||

Company Advantage | 1. Quotation within 48 hours. 2. Quality you can rely on. 3. Zehan provides 100% satisfaction at world competitive prices. 4. We pay meticulous attention to details throughout the whole manufacturing process. 5. Rigorous QC standards, 100% inspection before shipping. 6. Strict delivery time control for each and every order. | ||||||

Company Profile

Qingdao Zehan Machinery Manufacturing Co., Ltd is a leading international manufacturer with 15+ years of group experience in rapid prototyping and production for metal & plastic components. We are an export-oriented high-tech enterprise specializing in fabrication of high-end metal parts, keeping a long-term and stably strategic cooperation with a number of world-famous enterprises. Our products are widely used in precision equipment, engineering machinery, construction machinery, power facility, agricultural machinery, animal husbandry, aviation, rail traffic and other industries. They have been widely sold in high-end market like North American and European countries.

As a leading components manufacturing enterprise integrating with the digital management and production technology, Zehan has successively passed and introduced ISO9001 quality system, ERP management system, DNC system and PLM system. CNC equipment, automatic machines and auto test facilities are employed in all processing and manufacturing sectors. Covering extensive & well-adapted types, some machines have already reached the world class level. It is our consistent tenet to pursue quality and make every product with high-qualitymaterials, Scientific design and exquisite process.

Qingdao Zehan Machinery Manufacturing Co., Ltd. sincerely welcomes more friends to cooperate with us, and create a better future together.

Qingdao Zehan Machinery Manufacturing Co., Ltd. sincerely welcomes more friends to cooperate with us, and create a better future together.

Testing Equipments

Our Service

Zehan CNC Machining Service

We have multiple CNC machining equipments and 3/4/5 axis machining centers for turning, milling, drilling, boring and tapping process with brass, aluminum, stainless steel, iron, plastic and titanium alloy and other materials. Zehan can provide customers with a range of services from designing, processing to surface treatment.

Materials

Application Field

Customers VIsiting

FAQ

1.Which materials are used in CNC machining?

Almost any material can be used in a CNC machine. It really depends on the application. Common materials include metals such as aluminum, brass, copper, steel, and titanium, as well as wood, foam, fiberglass, and plastics such as polypropylene, ABS, POM, PC, Nylon, etc.

2.How Does CNC machining Work?

When a CNC system is activated, the desired cuts are programmed into the software and dictated to corresponding tools and machinery, which carry out the dimensional tasks as specified, much like a robot. In CNC programming, the code generator within the numerical system will often assume mechanisms are flawless, despite the possibility of errors, which is greater whenever a CNC machine is directed to cut in more than one direction simultaneously. The placement of a tool in a numerical control system is outlined by a series of inputs known as the part program.

Almost any material can be used in a CNC machine. It really depends on the application. Common materials include metals such as aluminum, brass, copper, steel, and titanium, as well as wood, foam, fiberglass, and plastics such as polypropylene, ABS, POM, PC, Nylon, etc.

2.How Does CNC machining Work?

When a CNC system is activated, the desired cuts are programmed into the software and dictated to corresponding tools and machinery, which carry out the dimensional tasks as specified, much like a robot. In CNC programming, the code generator within the numerical system will often assume mechanisms are flawless, despite the possibility of errors, which is greater whenever a CNC machine is directed to cut in more than one direction simultaneously. The placement of a tool in a numerical control system is outlined by a series of inputs known as the part program.

With a numerical control machine, programs are inputted via punch cards. By contrast, the programs for CNC machines are fed to computers though small keyboards. CNC programming is retained in a computer’s memory. The code itself is written and edited by programmers. Therefore, CNC systems offer far more expansive computational capacity. Best of all, CNC systems are by no means static, since newer prompts can be added to pre-existing programs through revised code.

3.What are different types of machining?

3.What are different types of machining?

Turning- Turning or Lathing involves rotating the workpiece on a machine, while a single-edged cutting tool remains stationary. The cutting tool is slowly moved parallel to the workpiece’s rotational axis, removing material as it goes.

Drilling - Drilling results in creating a round hole by rotating a cylindrical tool parallel to the workpiece’s axis of rotation. The hole created is equal in diameter of the tool that was used.

Milling - Milling is the process of removing material, using rotary cutters, from a workpiece in a feed motion perpendicular to the rotational axis of the cutting tool. This is one of the most common forms of machining used today.

4.What is the difference between CNC milling and CNC lathe?

A lathe turns the material you’re machining and the tools are held stationary in the turret. Lathes are used mainly for round parts. Milling machines hold the material stationary and the tools do the movement.Milling machines are used for any shape part.

5. What’s the difference between the Vertical and Horizontal CNC machines?

5. What’s the difference between the Vertical and Horizontal CNC machines?

There are two main spindle orientations in CNC machining. In vertical CNC machines, the spindle axis, which is called the z-axis, is oriented vertically. In a C-column configuration, the spindle travels in this direction, and the table which holds the workpiece moves in both x and y horizontal directions. Vertical machines are perfect for projects milled from one side, such as covers and brackets.

In horizontal CNC machines, the spindle z-axis is horizontal and typically parallel to the length of the machine. The spindle travels the vertical y-axis and horizontally in the x-axis. The pallet and fixtures hold the workpiece and move in the z-axis, and the B-axis rotates. Horizontal machining has several advantages including accessing machining from four sides and better chip evacuation. Typically, heavy workpieces are a better fit for horizontal machines the machines are more sturdy, include pallet changers, hold more tools, and can be more easily loaded and accessed by the spindle using B-axis rotations.

6. How does ZH ensure the quality of my parts?

Once your order is confirmed, we will execute the whole fabricate design (DFM) review, so that our engineer think that maybe affect any quality problems of your parts.Using a set of test equipment to check and confirm the all materials.The final inspection report before shipping.

Product Categories : CNC Machining Parts > CNC Machining Parts

Premium Related Products

Other Products

Hot Products

Custom High Precision Casting Mercedes Benz Truck PartsFoundry Good Quality Precision Iron Casting for PumpOEM Precision Stainless Steel Die Casting Spin ManufacturerSupplier Custom Good Quality High Precision Steel CastingChina Foundry Custom High Quality Casting Aluminiumprecision aluminum die casting housing partzinc die casting clock frameDifferent kind of stamping partPart made by plastic injectionAluminum Die Casting Part with ISO9001die casting mould makingCNC machining partPar38 heatsinkAluminum die casting partDie casting partanodizing part